-

High-quality

Raw materials

-

Deep understanding of

The process

-

Comprehensive quality

Control system

-

Cost-effective

Products

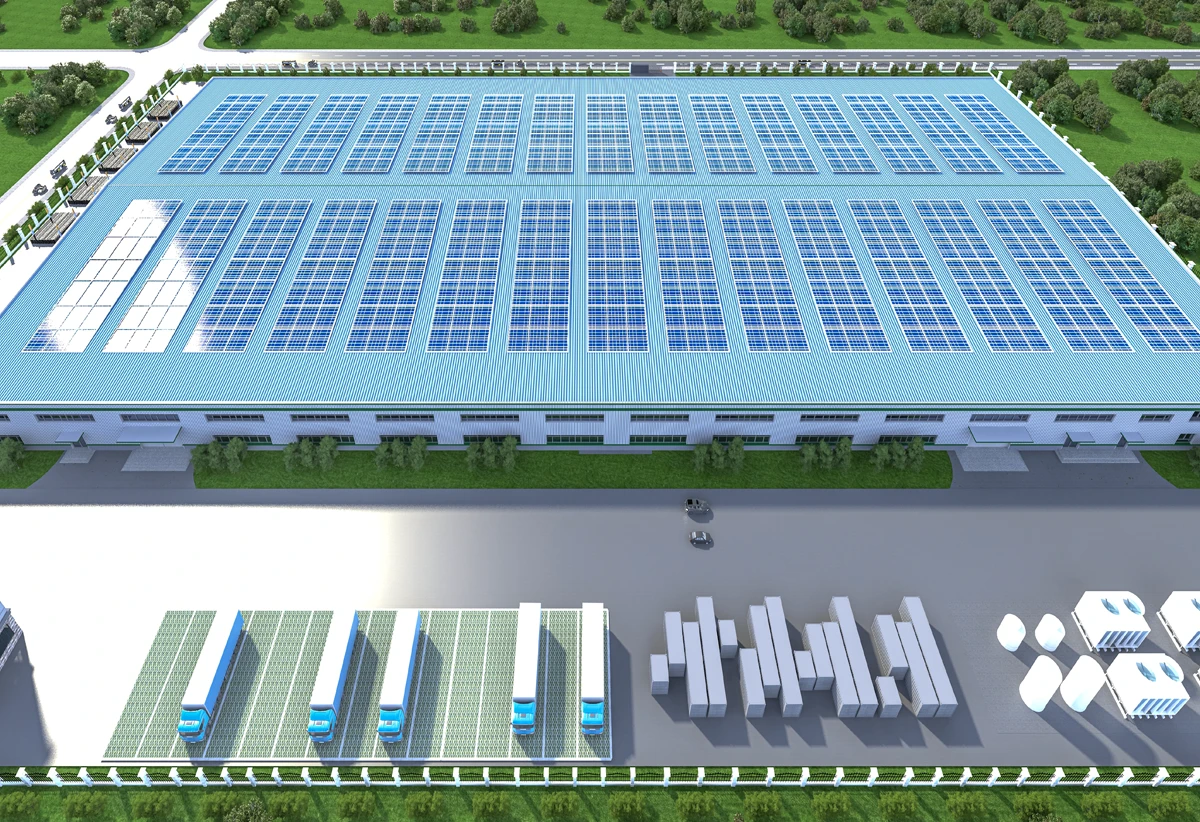

G-Star focuses on vertically integrating the production process, with a perfect own vertically integrated production plant and professional manufacturing team, which can realize effective cost control and enhance the competitive advantage of product price.

We strictly control the quality of raw materials, fully implement the quality control system, and strictly implement international standards and certification systems throughout the production process.G-STAR products have obtained ISO9001 quality management system certification, ISO14001 environmental management system certification, ISO45001 occupational health and safety system certification, TUV, CEC, ETL, CE, DEKRA, BIS and many other international authoritative product certificates, we can ensure the reliability and excellent quality of our products while providing price advantages.